Harness Higher Quality With Maxi-Seal® Technology

Peterson sets the industry standard for durability, designing trailer wiring harnesses that outlast the toughest conditions. Every Peterson harness is engineered with Maxi-Seal® Technology, providing superior moisture protection and precision-sealed wiring built to your specifications. Even our standard harnesses include major performance upgrades.

10-yr warranty

The Defender® brand Harness and Lighting System are warranted to the original purchaser against corrosion damage caused by the failure of the light or wiring harness for a period of ten (10) years from the date of shipment.

MODULAR DESIGN

built-in strain relief

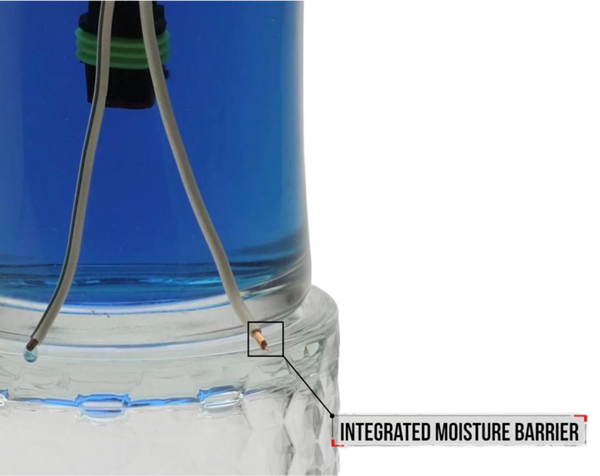

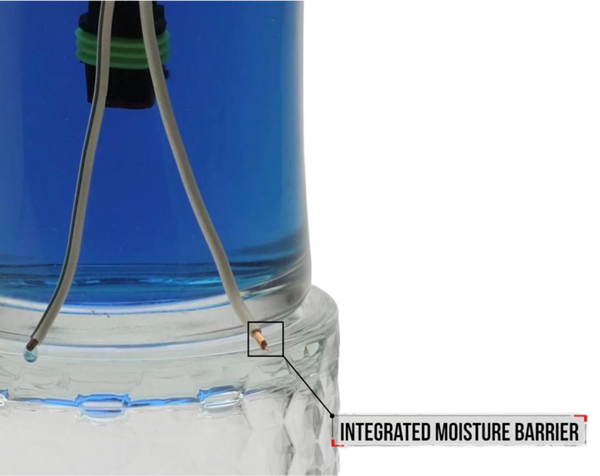

INTEGRATED MOISTURE BARRIER (IMB®)

A built-in moisture barrier prevents water from wicking through the wiring, stopping corrosion before it spreads across the entire harness. This system-wide protection keeps electrical connections dry, ensuring long-term reliability in harsh environments.

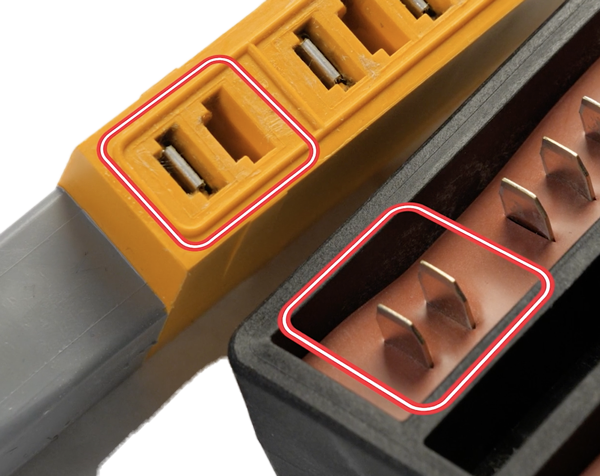

Advanced J560 Connectors

Peterson’s J560 connectors are offered in a variety of configurations and angles for every application and offer rigid polymer molding and an engineering-grade resin over mold. Our patented snap-on flange means no pull through is needed for installation and a pliable, molded-in gasket ensures secure seating.

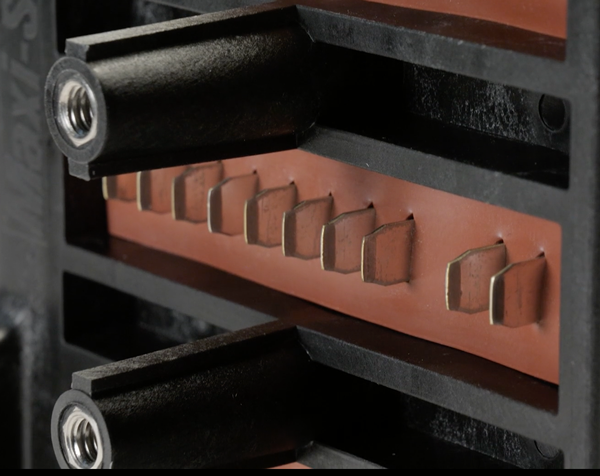

HEAVY DUTY TERMINALS

Peterson’s 5/8-inch blade terminals are thicker and wider than industry standards, ensuring a stronger, more reliable electrical connection. Their increased surface area minimizes voltage drop, improving power efficiency across the harness and wiring system.

DUAL-ISOLATED GROUNDING

Advanced Breakout Design

ADVANCED SILICONE SEALS

Durable silicone seals used in the Defender´® module create a watertight shield at critical connection points, blocking moisture where wires and terminals meet. Their flexible, high-strength design maintains a secure seal against vibration, temperature changes, and road debris.

advanced BULLET CONNECTORS

Peterson's .180 bullet connectors feature molded-in O-rings and detents, providing secondary locking for improved sealing and reliable electrical connections. The secure fit minimizes vibration-related failures, ensuring long-lasting performance in harsh environments.

SEALED RING TERMINALS

Sealed ring terminals use adhesive-filled, heat-shrink connectors that completely encase the copper conductor for maximum corrosion protection. The barrier prevents moisture intrusion, extending the lifespan of electrical connections in demanding conditions.

5-yr warranty

The PetersonPATRIOT® brand Harness and Lighting System are warranted to the original purchaser against corrosion damage caused by the failure of the light or wiring harness for a period of five (5) years from the date of shipment.

COLOR-CODED CENTRAL HUB

PetersonPATRIOT® features a one-way, color-coded connectors and labeled central hub to make installation fast and foolproof. And if there’s ever an issue, it's easy to isolate and replace a damaged cable without disrupting the rest of the system—saving time, effort, and downtime.

Built-In Strain Relief

Integrated into the color-coded distribution module, PetersonPATRIOT’s strain relief system adds another layer of durability by minimizing stress on connections and preserving performance.

INTEGRATED MOISTURE BARRIER®

A built-in moisture barrier prevents water from wicking through the wiring, stopping corrosion before it spreads across the entire harness. This system-wide protection keeps electrical connections dry, ensuring long-term reliability in harsh environments.

Advanced Connectors

Advanced BREAK-OUT DESIGN

A 2-stage over-molding process fully encapsulates splices, adding strain relief and blocking moisture intrusion. Ultrasonically welded splices with adhesive-lined heat shrink tubing create a durable, sealed connection that resists road chemicals and environmental damage.

advanced BULLET CONNECTORS

Peterson's .180 bullet connectors feature molded-in O-rings and detents, providing secondary locking for improved sealing and reliable electrical connections. The secure fit minimizes vibration-related failures, ensuring long-lasting performance in harsh environments.

SEALED RING TERMINALS

Sealed ring terminals use adhesive-filled, heat-shrink connectors that completely encase the copper conductor for maximum corrosion protection. The barrier prevents moisture intrusion, extending the lifespan of electrical connections in demanding conditions.

3-yr warranty

The Maxi-Seal® Harness and Lighting System are warranted to the original purchaser against corrosion damage caused by the failure of the light or wiring harness for a period of three (3) years from the date of shipment.

Advanced J560 Connectors

Peterson’s J560 connectors are offered in a variety of configurations and angles for every application and offer rigid polymer molding and an engineering-grade resin over mold. Our patented snap-on flange means no pull through is needed for installation and a pliable, molded-in gasket ensures secure seating.

Advanced BREAK-OUT DESIGN

A 2-stage over-molding process fully encapsulates splices, adding strain relief and blocking moisture intrusion. Ultrasonically welded splices with adhesive-lined heat shrink tubing create a durable, sealed connection that resists road chemicals and environmental damage.

advanced BULLET CONNECTORS

Peterson's .180 bullet connectors feature molded-in O-rings and detents, providing secondary locking for improved sealing and reliable electrical connections. The secure fit minimizes vibration-related failures, ensuring long-lasting performance in harsh environments.

SEALED RING TERMINALS

Sealed ring terminals use adhesive-filled, heat-shrink connectors that completely encase the copper conductor for maximum corrosion protection. The barrier prevents moisture intrusion, extending the lifespan of electrical connections in demanding conditions.

WARRANTY

10-yr warranty

The Defender® brand Harness and Lighting System are warranted to the original purchaser against corrosion damage caused by the failure of the light or wiring harness for a period of ten (10) years from the date of shipment.

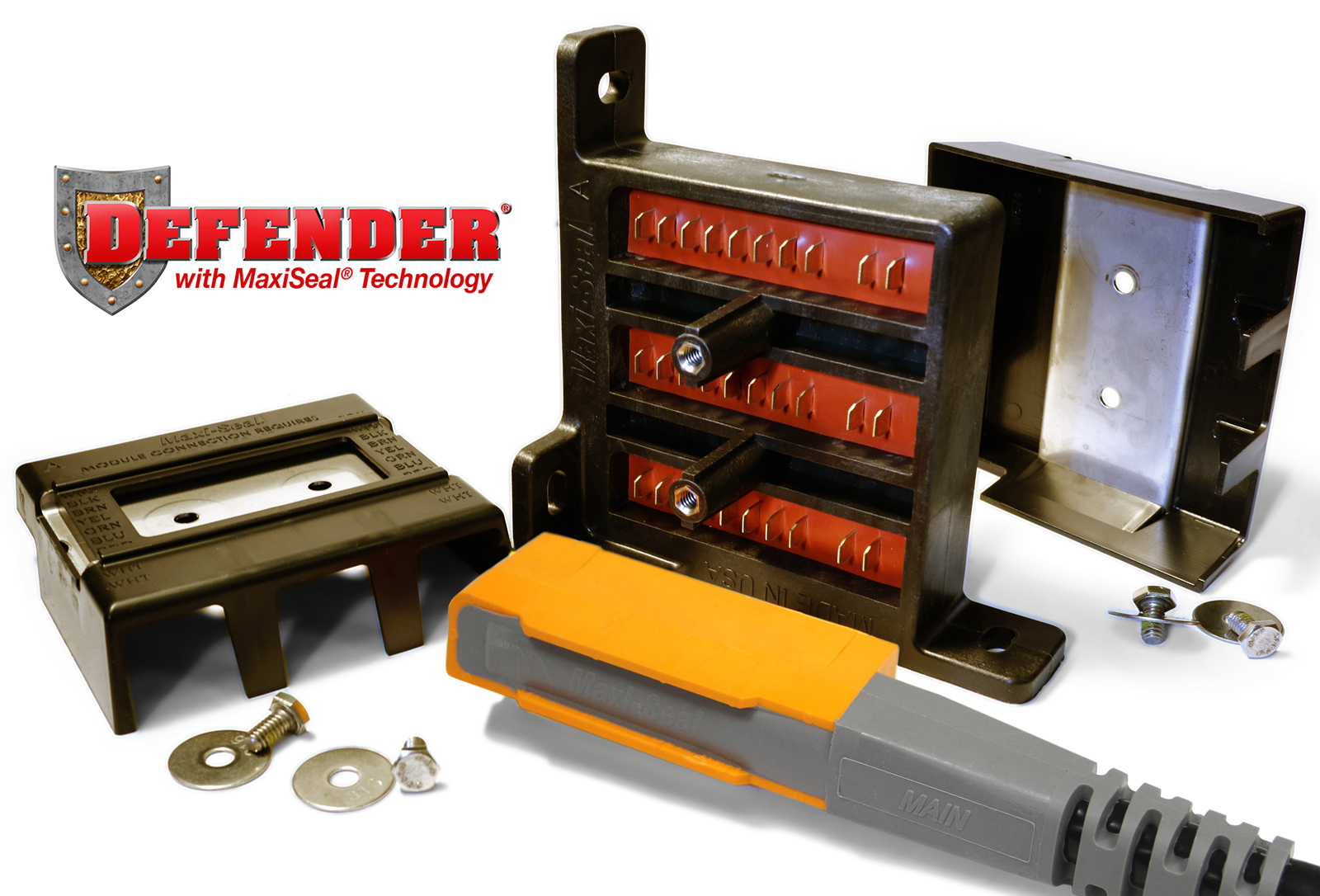

Modular design

Modular design

Peterson’s Defender® Harness system features a modular design which can be completely customized to any user’s application. This design streamlines assembly, making troubleshooting and repairs faster, easier, and more cost-effective.

Built-In Strain Relief

Built-In Strain Relief

The integrated strain relief on the Defender® harness system minimizes mechanical stress on wiring connections, helping to prevent damage from vibration, flexing, and environmental impact.

integrated moisture barrier (IMB®)

integrated moisture barrier

A built-in moisture barrier prevents water from wicking through the wiring, stopping corrosion before it spreads across the entire harness. This system-wide protection keeps electrical connections dry, ensuring long-term reliability in harsh environments.

advanced J560 connectors

advanced J560 connectors

Peterson’s J560 connectors are offered in a variety of configurations and angles for every application and offer rigid polymer molding and an engineering-grade resin over mold. Our patented snap-on flange means no pull through is needed for installation and a pliable, molded-in gasket ensures secure seating.

heavy duty terminals

heavy duty terminals

Peterson’s 5/8-inch blade terminals are thicker and wider than industry standards, ensuring a stronger, more reliable electrical connection. Their increased surface area minimizes voltage drop, improving power efficiency across the harness and wiring system.

dual-isolated grounding

dual-isolated grounding

Defender® features an advanced grounding system to prevent galvanic corrosion and protect electrical components from premature failure. Dual grounding increases current carrying capacity and ensures consistent power distribution across the entire Defender® harness. IP69K certified.

Advanced BREAK-OUT DESIGN

Advanced BREAK-OUT DESIGN

A 2-stage over-molding process fully encapsulates splices, adding strain relief and blocking moisture intrusion. Ultrasonically welded splices with adhesive-lined heat shrink tubing create a durable, sealed connection that resists road chemicals and environmental damage.

advanced silicone seals

advanced silicone seals

Durable silicone seals used in the Defender´® module create a watertight shield at critical connection points, blocking moisture where wires and terminals meet. Their flexible, high-strength design maintains a secure seal against vibration, temperature changes, and road debris.

advanced Bullet connectors

advanced Bullet connectors

Peterson's .180 bullet connectors feature molded-in O-rings and detents, providing secondary locking for improved sealing and reliable electrical connections. The secure fit minimizes vibration-related failures, ensuring long-lasting performance in harsh environments.

Sealed ring terminals

Sealed ring terminals

Sealed ring terminals use adhesive-filled, heat-shrink connectors that completely encase the copper conductor for maximum corrosion protection. The barrier prevents moisture intrusion, extending the lifespan of electrical connections in demanding conditions.

WARRANTY

5-yr warranty

The PetersonPATRIOT® brand Harness and Lighting System are warranted to the original purchaser against corrosion damage caused by the failure of the light or wiring harness for a period of five (5) years from the date of shipment.

color-coded distribution hub

color-coded central hub

PetersonPATRIOT® features a one-way, color-coded connectors and labeled central hub to make installation fast and foolproof. And if there’s ever an issue, it's easy to isolate and replace a damaged cable without disrupting the rest of the system—saving time, effort, and downtime.

Built-In Strain Relief

Built-In Strain Relief

Integrated into the color-coded distribution module, PetersonPATRIOT’s strain relief system adds another layer of durability by minimizing stress on connections and preserving performance.

integrated moisture barrier®

integrated moisture barrier

A built-in moisture barrier prevents water from wicking through the wiring, stopping corrosion before it spreads across the entire harness. This system-wide protection keeps electrical connections dry, ensuring long-term reliability in harsh environments.

advanced J560 connectors

advanced J560 connectors

Peterson’s J560 connectors are offered in a variety of configurations and angles for every application and offer rigid polymer molding and an engineering-grade resin over mold. Our patented snap-on flange means no pull through is needed for installation and a pliable, molded-in gasket ensures secure seating.

Advanced BREAK-OUT DESIGN

Advanced BREAK-OUT DESIGN

A 2-stage over-molding process fully encapsulates splices, adding strain relief and blocking moisture intrusion. Ultrasonically welded splices with adhesive-lined heat shrink tubing create a durable, sealed connection that resists road chemicals and environmental damage.

advanced Bullet connectors

advanced Bullet connectors

Peterson's .180 bullet connectors feature molded-in O-rings and detents, providing secondary locking for improved sealing and reliable electrical connections. The secure fit minimizes vibration-related failures, ensuring long-lasting performance in harsh environments.

Sealed ring terminals

Sealed ring terminals

Sealed ring terminals use adhesive-filled, heat-shrink connectors that completely encase the copper conductor for maximum corrosion protection. The barrier prevents moisture intrusion, extending the lifespan of electrical connections in demanding conditions.

WARRANTY

3-yr warranty

The Maxi-Seal® Harness and Lighting System are warranted to the original purchaser against corrosion damage caused by the failure of the light or wiring harness for a period of three (3) years from the date of shipment.

advanced J560 connectors

advanced J560 connectors

Peterson’s J560 connectors are offered in a variety of configurations and angles for every application and offer rigid polymer molding and an engineering-grade resin over mold. Our patented snap-on flange means no pull through is needed for installation and a pliable, molded-in gasket ensures secure seating.

Advanced BREAK-OUT DESIGN

Advanced BREAK-OUT DESIGN

A 2-stage over-molding process fully encapsulates splices, adding strain relief and blocking moisture intrusion. Ultrasonically welded splices with adhesive-lined heat shrink tubing create a durable, sealed connection that resists road chemicals and environmental damage.

advanced Bullet connectors

advanced Bullet connectors

Peterson's .180 bullet connectors feature molded-in O-rings and detents, providing secondary locking for improved sealing and reliable electrical connections. The secure fit minimizes vibration-related failures, ensuring long-lasting performance in harsh environments.

Sealed ring terminals

Sealed ring terminals

Sealed ring terminals use adhesive-filled, heat-shrink connectors that completely encase the copper conductor for maximum corrosion protection. The barrier prevents moisture intrusion, extending the lifespan of electrical connections in demanding conditions.

Defender® HARNESS

Peterson Defender® is for fleets that run hard and expect their equipment to do the same.

When uptime matters, trust the harness system that’s proven itself over billions of real-world miles. The Peterson Defender® Harness System is engineered for unmatched protection against corrosion, moisture, and lighting failures—delivering the rugged reliability other systems only claim.

Defender® features a centralized hub with heavy-duty terminals and an integrated moisture barrier or IMB® that locks out contaminants and eliminates weak points. The system’s modular design simplifies installation and maintenance while standing up to the chemical cocktails lurking on today’s roads that eat trailers and electric systems alive. Defender® is built to dominate in punishing conditions—backed by a 10-year warranty.

With a failure rate of less than 0.001%, Defender® doesn’t just perform—it saves. Imagine how much you could cut in maintenance costs, downtime, and FMCSA citations with Defender® on every trailer. In fact, just one avoided repair could cover the cost difference compared to a standard harness system.

Need Next steps for defender?

PetersonPATRIOT® HARNESS

PetersonPATRIOT® IS FOR FLEETS THAT WANT DEPENDABLE PERFORMANCE—WITHOUT OVERSPENDING TO GET IT.

When corrosion strikes competitor harnesses, PetersonPATRIOT® fights back—cutting downtime, repair costs, and FMCSA lighting violations. With just one fewer trip to the repair shop covering the cost difference between PetersonPATRIOT® and a standard harness system, it’s a smart choice for fleets.

The PetersonPATRIOT® Modular Harness System is engineered to resist moisture, road grime, and wear, keeping your trailer lighting running strong, mile after mile.

It’s modular, plug-and-play design features over-molded connectors, our patented Integrated Moisture Barrier®, and a flexible layout that adapts to to your fleet’s needs. A color-coded central hub with one-way, “poka-yoke” connections makes installation fast and foolproof, while the compact footprint allows for versatile mounting options.

Paired with Peterson’s LumenX® LED lighting and backed by a five-year warranty against defects and corrosion, PetersonPATRIOT® delivers long-term reliability and simplified maintenance.

NEED NEXT STEPS WITH PetersonPATRIOT®?

Maxi-Seal® HARNESS

Maxi-Seal® is the dependable choice for fleets that need proven durability at a practical price.

For over 25 years, Maxi-Seal® has been the trusted choice for sealed wiring harness systems in the light, medium, and heavy-duty trailer markets. Built on a legacy of reliability and precision, Maxi-Seal® continues to evolve—offering enhanced durability, smarter design, and proven performance mile after mile.

Engineered with a two-stage overmolded process, flexible strain relief, and advanced breakout design, Maxi-Seal® delivers a secure, long-lasting connection in tough conditions.

The upgraded J560 connector and .180 bullet connectors with molded O-rings and detents provide tight, moisture-resistant seals, while sealed ring terminals help guard against corrosion.

Whether you’re wiring a single trailer or scaling across an entire fleet, Maxi-Seal® offers practical, dependable performance backed by a 3-year warranty against defects.

Ready for Next steps?

Find the Right Harness for Your Application

| Harness features | Defender® | PetersonPatriot® | Maxi-Seal® | |

|---|---|---|---|---|

| 10-year Warranty Against Defects and Corrosion | X | |||

| 5-year Warranty Against Defects and Corrosion | X | |||

| 3-year Warranty Against Defects | X | |||

| Color Coded Distribution Hub | X | |||

| Modular Design | X | X | ||

| Built-In Strain Relief | X | X | ||

| IMB™ – Integrated Moisture Barrier | X | X | ||

| Advanced J560 Connectors | X | X | X | |

| Heavy-Duty Terminals | X | |||

| Dual Isolated Grounding | X | |||

| Advanced Break-Out Design | X | X | X | |

| Advanced Silicone Seals | X | X | ||

| Advanced Bullet Connectors | X | X | X | |

| Sealed Ring Terminals | X | X | X | |

Ready to learn more?

HOURs

M-F 8:00am-5:00pm (CT)

Address

4200 E. 135th Street Grandview, MO 64030

Phone

816.765.2000

toll-free

1.800.821.3490

fax

816.761.6693