Industry-Leading Innovation So You Can Lead Your Fleet

Peterson has a proud legacy of industry innovations, from pioneering advanced corrosion-resistant lighting and harness systems to leading the way in open-source trailer telematics.

- 9First ISO 9001/QS-9000-certified U.S. lighting manufacturer

- 9First multi-function LED strobe and turn lights for the refuse industry

- 9First single-diode 4” LED round lights for intermodal chassis

- 9First to use insert-molding technology in trailer lighting and harness systems

- 9First guaranteed moisture corrosion-proof harness and lighting technology

- 9First open-source whole-trailer telematics with real-time fleet monitoring

- 9First to introduce white LEDs under colored lenses, setting a new industry standard

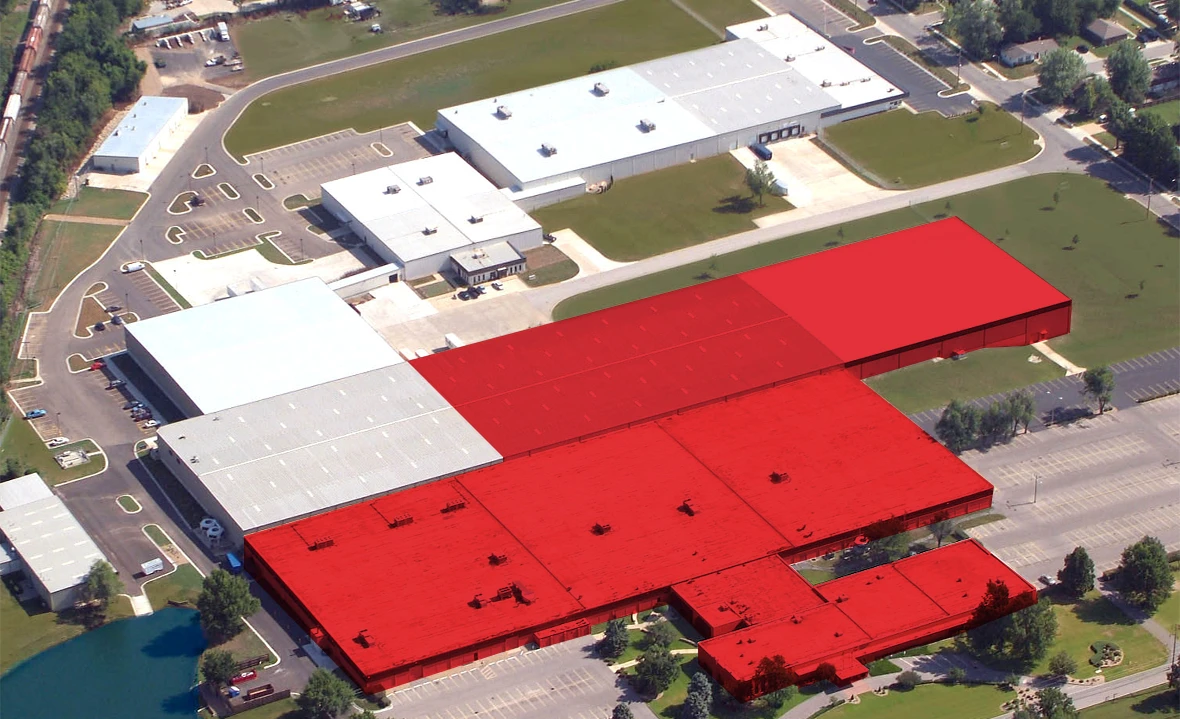

Engineered. Tested. Built. Delivered. All in One Place.

With four vertically integrated factories in our 670,000-square-foot facility, Peterson is the only lighting and harness manufacturer to design, engineer, test, and produce products in-house and under one roof.

Custom Solutions That Go Beyond Expectations

Peterson delivers purpose-built solutions tailored for how your fleet actually runs, repairs, hauls, and performs.

PRECISION ENGINEERING. PURPOSE-DRIVEN PARTNERSHIPS.

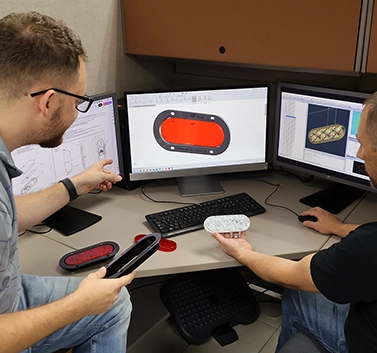

From first sketch to final production, Peterson’s dedicated engineering team partners with you at every stage.

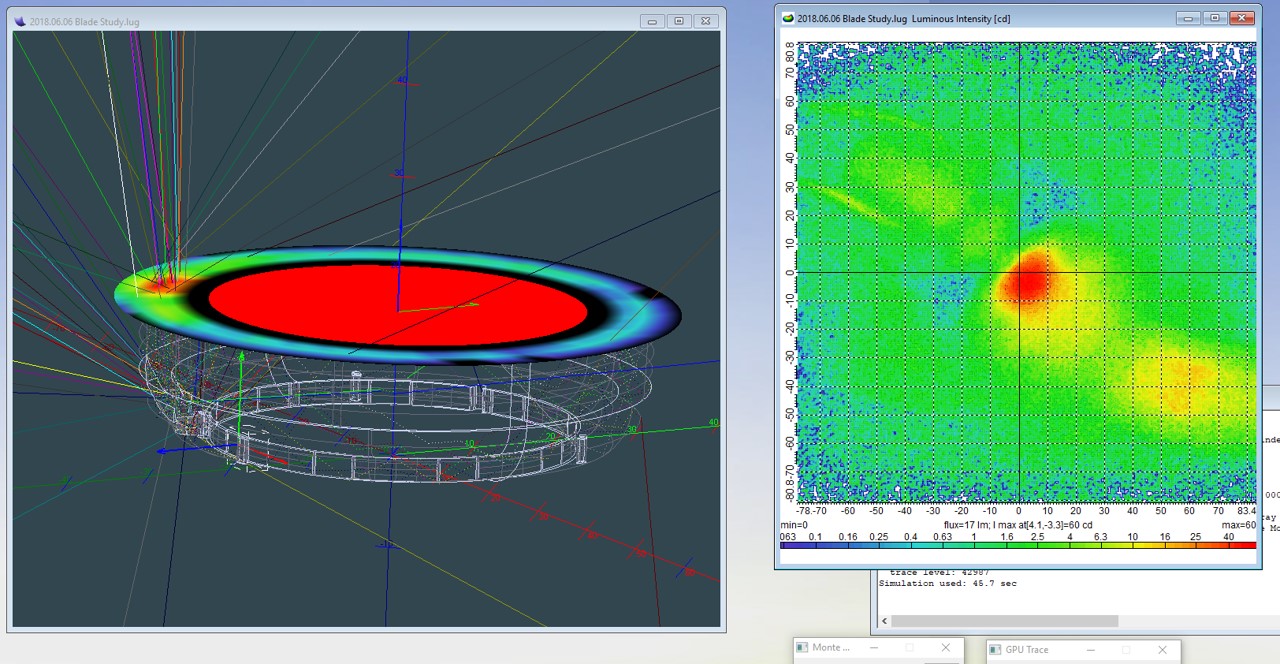

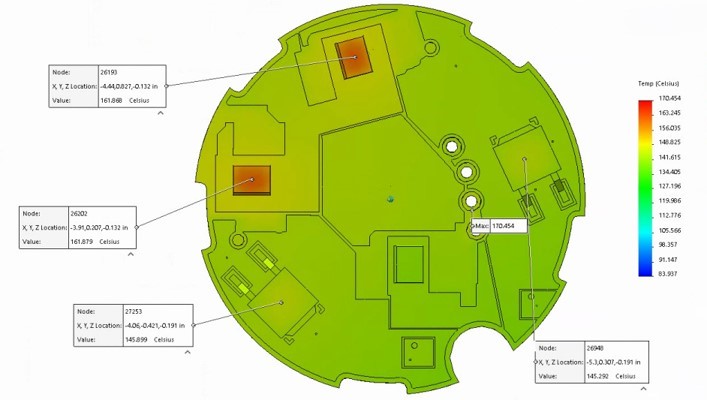

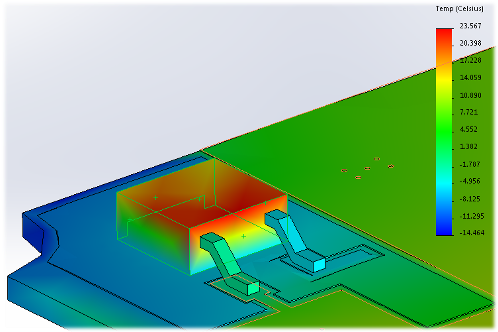

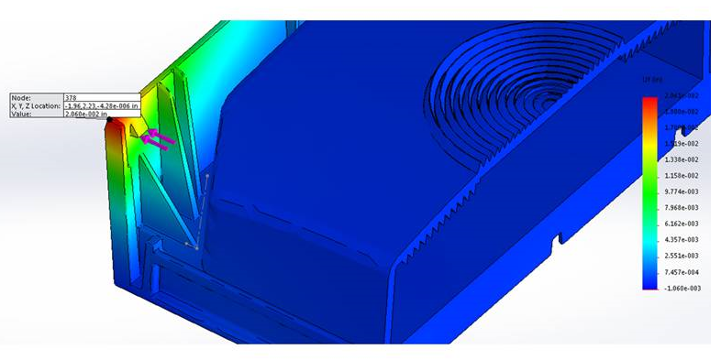

We apply optical design and ray-trace analysis to predict system performance and refine configurations early. FEA simulations validate thermal, optical, and structural integrity, while 3D printing enables fast-turn prototypes for testing and iteration.

We catch issues before they become problems, speeding development, reducing rework, and getting your solutions road-ready faster.

Every product reflects deep collaboration, smarter design, and the assurance that your goals shape our process.

STRONG CONNECTIONS. ZERO COMPROMISE.

State-of-the-art LED lighting comes from utilizing the most advanced engineering design and simulation tools available.

With solid modeling, we are able to conduct Finite Element Analysis, otherwise known as FEA. We can then simulate for stresses and vibration analysis, as well as thermal simulation well before we start making tools. We are able to understand the limits of the design, and can make amendments to the design to reduce the stresses to acceptable levels.

Altium is the industry leader in PCB design, and our electrical engineers use this tool to create the printed circuit boards for the LED lamps. Altium provides full schematic design for the printed circuit board. In addition, it provides simulation of the electrical circuit. Along with our in-house, automated surface-mounted technology Peterson gives you full flexibility in PCB design and precision component placement.

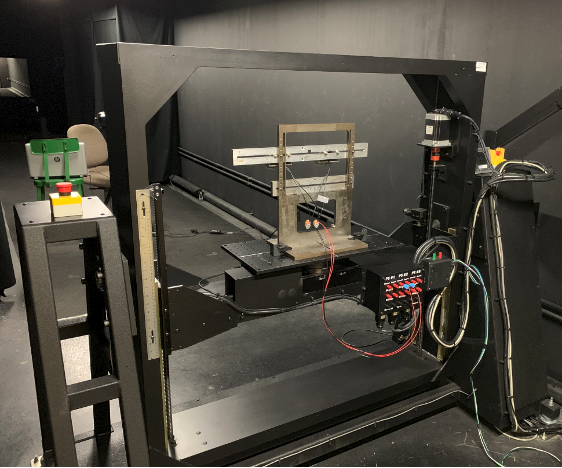

TESTED TO PERFORM. BUILT TO LAST.

Real-world results require real testing. Our in-house photometry and metrology labs, infrared thermal imaging, and thermocouple sensing simulate extreme heat, cold, vibration, and impact to ensure every lighting product and harness system meets the toughest standards before it ever hits the road.

Our in-house plastics engineering team, including a 50-press molding department, produces high-strength, tight-tolerance components built to handle real-world stress.

From materials selection to environmental validation, Peterson designs durability into every detail. We help you reduce failure risks, avoid compliance issues, and keep your equipment reliable through harsh weather, long hauls, and years of rugged use.

NO LIMITS. JUST SOLUTIONS.

No two applications are the same, so we don’t expect you to settle for one-size-fits-all. Whether you’re building a small fleet upgrade or launching a next-gen trailer line, Peterson customizes every lighting and harness solution to your exact specs and schedule.

No ideation is too unique. We combine modular harness layouts, scalable production lines, and a flexible, cross-functional development process to keep you in control. Tight timeline? Unique configuration? High complexity? We adapt fast and deliver with confidence because real flexibility means more than features; it means getting exactly what you need exactly when you need it.

READY TO LEARN MORE?

HOURs

M-F 8:00am-5:00pm (CT)

Address

4200 E. 135th Street Grandview, MO 64030

Phone

816.765.2000

toll-free

1.800.821.3490

fax

816.761.6693